Recently, Konstantin Babkin, co-owner of the Rostov Agricultural Machinery Plant, gave a candid interview to Kommersant, openly discussing the challenges facing his enterprise and the systemic crisis in the domestic agricultural machinery sector. His remarks were sharp and unvarnished. Frankly, it’s been a long time since I’ve seen a high-profile figure speak so bluntly about problems in public—after all, television is saturated with narratives of growth, breakthroughs, and achievements, while real issues are deliberately swept under the rug.

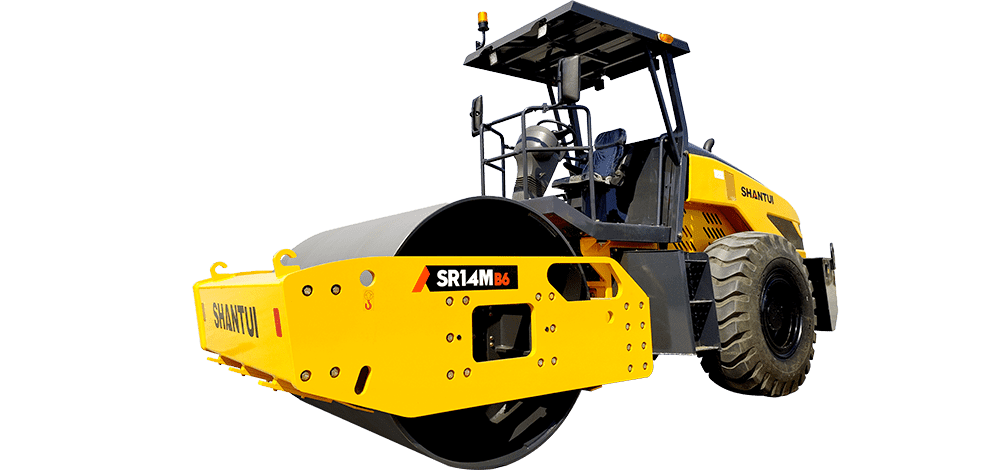

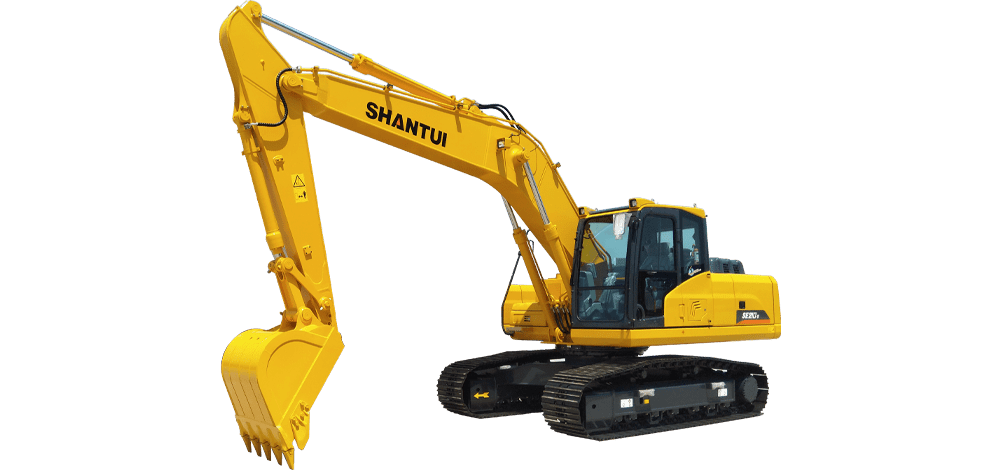

Over my thirty years working in industry media, I’ve had in-depth conversations with hundreds of industrial entrepreneurs—from general directors to business owners—and recent discussions are no exception. In private, everyone laments the economic crisis in Russia: the collapse of specialized Construction equipment, plummeting production and sales, companies forced to implement reduced workweeks, import substitution remaining an empty slogan, and the government’s lack of substantive protection for domestic machinery manufacturing.

Here are the key issues Babkin highlighted:

- Precipitous Market Decline

In January-February 2025, the agricultural machinery market shrank by over 30% year-on-year, following 2024, which was already the worst year in a decade for the industry and the Rostov plant. Companies have been forced to slash investments, and the entire sector has entered austerity mode. - Triple Stranglehold Mechanism

Sky-high benchmark interest rates draining capital from the real economy

Sharp cuts in state subsidies

Grain export tariffs suppressing domestic market prices

The result? Agricultural producers have lost the incentive to upgrade their machinery

3.The Death Spiral of Overcapacity and Inventory

As of March 12, 2025, inventory at the top ten agricultural machinery plants surged by 72% year-on-year (36 billion → 62 billion rubles), equivalent to 25% of annual production sitting idle. At the Rostov plant, 40% of finished products remain stranded in storage yards.

4.Survival Layoffs and Abandoned Projects

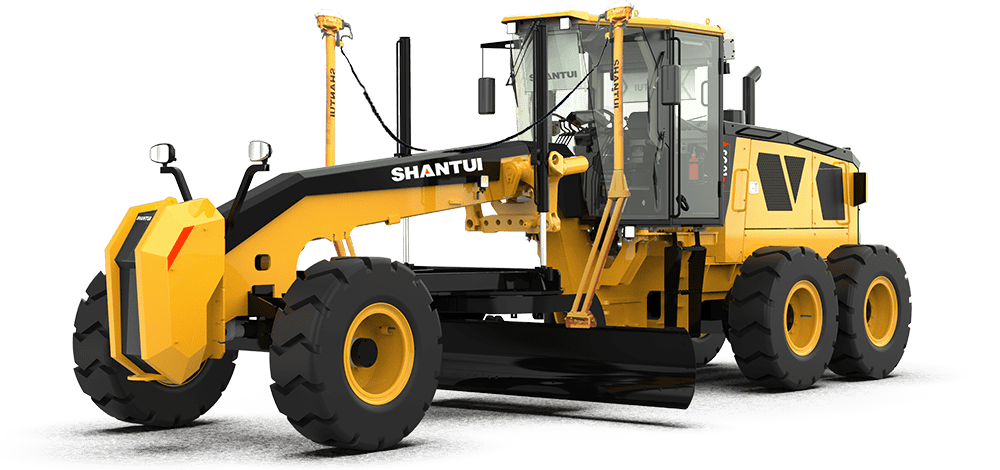

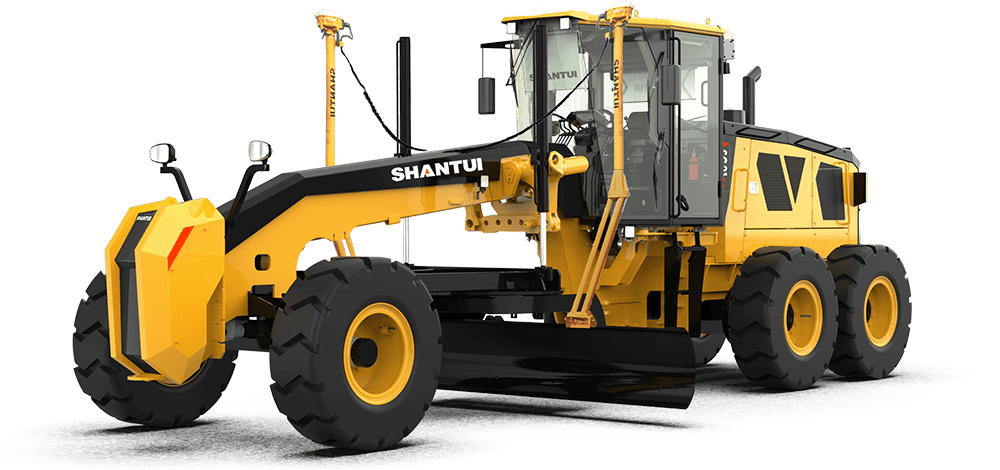

The company was forced to adopt a three-day workweek before eventually reverting to five days—but only after laying off 2,000 workers. Three newly built factories (a tractor plant, a gearbox plant, and a trailer equipment plant) now stand idle, while plans for a Mechanically operated grader line and foundry have been shelved indefinitely.

5.The Cost Paradox of Domestic Manufacturing

Steel prices are higher than in Germany

Electricity costs exceed those in Canada and China

Loan interest rates are far above those of international competitors

Overall production costs are 30% higher than in Germany, China, or Canada. Without tariff protections or subsidies, domestic manufacturing is doomed to fail.

Keywords:

- Construction machinery

- Construction equipment

- Mechanically operated grader

- 4. Construction machinery made in China