This year, the explosive growth of AI large models has spurred the construction machinery industry to accelerate its AI strategic deployment. Products combining construction machinery with AI continue to emerge and are gradually being applied across various construction scenarios. The technological iteration of “AI + construction machinery” has become a dominant trend in the industry. Industry insiders point out that breakthroughs in AI intelligence are expected to reshape the competitive landscape and further advance the position of Construction equipment made in China enterprises in the global market.

First AI-Powered Intelligent Bulldozer Unveiled

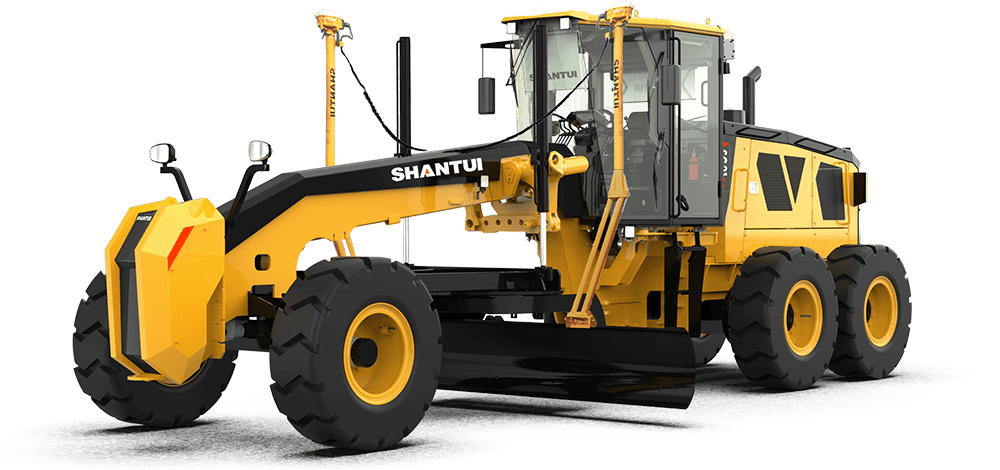

This year, as numerous AI companies, represented by DeepSeek, have launched various lightweight large-model frameworks, the construction machinery industry has also seized the opportunity to introduce related products. On June 19, Shantui Co., Ltd. held an AI strategy launch event and inaugurated its comprehensive testing center, unveiling the industry’s first AI-powered bulldozer in China.

Shantui explained that this AI bulldozer comprises two major modules—the intelligent machine and the AI smart assistant—and is designed around customer needs with nine intelligent systems covering core scenarios such as power optimization, construction safety, and collaborative operations. “The company conducted secondary development based on DeepSeek’s foundational model, deeply integrating it with the enterprise knowledge graph. Over six months, more than 100 technical personnel dedicated themselves to R&D, alongside over 25,000 field tests of intelligent bulldozers worldwide, to create a proprietary ‘AI decision-making model.’ This has enabled the company to transition from ‘smart equipment’ to ‘AI entities,'” Shantui stated.

It is understood that Shantui referenced the mature standards of autonomous driving in passenger vehicles and combined them with years of experience in intelligent construction to propose technical standards for the future development of AI in construction machinery.

According to Shantui’s AI classification system:

L1 marks the starting point of intelligence, where human operators control the equipment, and the AI assistant can understand simple commands.

L2 enables automatic control of the machine’s working devices.

L3 allows semi-automated construction, with remote cabins setting tasks and monitoring operations.

L4 achieves high automation, where the AI independently plans and optimizes construction schemes.

L5 realizes unmanned construction, with humans setting initial goals and the AI coordinating multi-machine collaborative operations.

“After years of technological accumulation, Shantui’s products have reached L3 intelligence and completed L4 technical reserves. Drivers will transition from ‘operators’ to ‘commanders,’ sitting in monitoring rooms to formulate work plans, schedule machine fleets (including excavators, loaders, and bulldozers) in real time, and oversee operations,” Shantui stated. “The AI assistant is no longer passive but begins to think proactively. Operators can detach from the equipment, set tasks in remote cabins, and monitor the construction process in real time. In specific scenarios and zones, the intelligent machine can automatically execute tasks, with human intervention available if anomalies arise.”

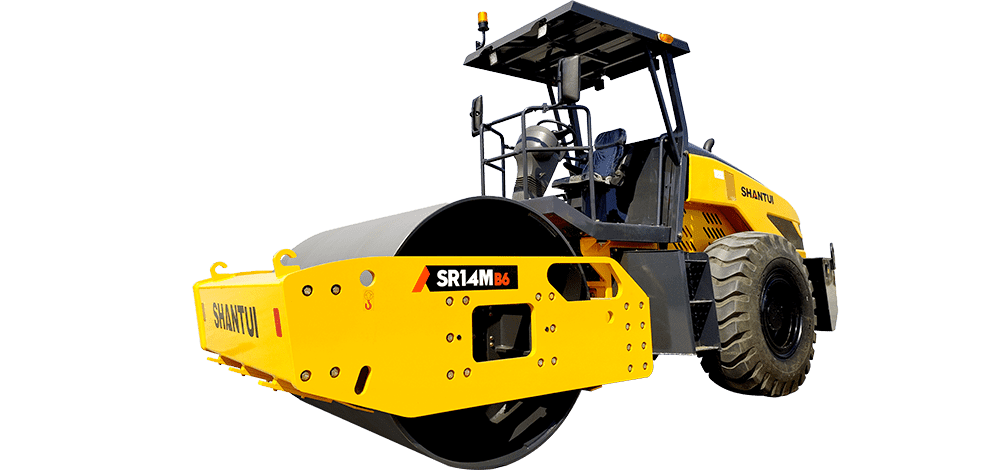

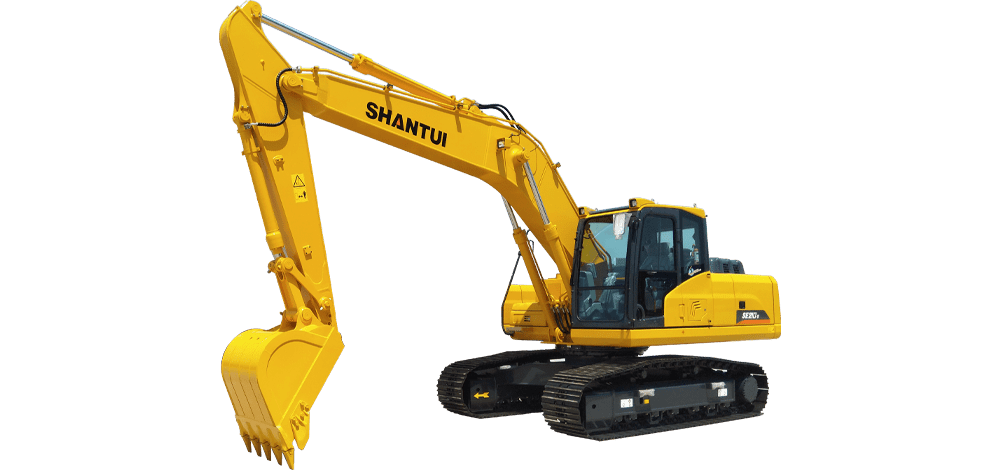

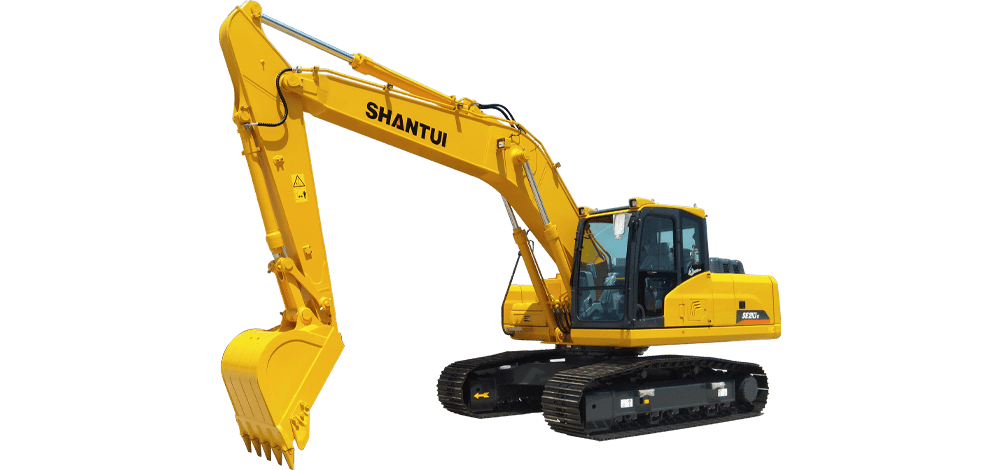

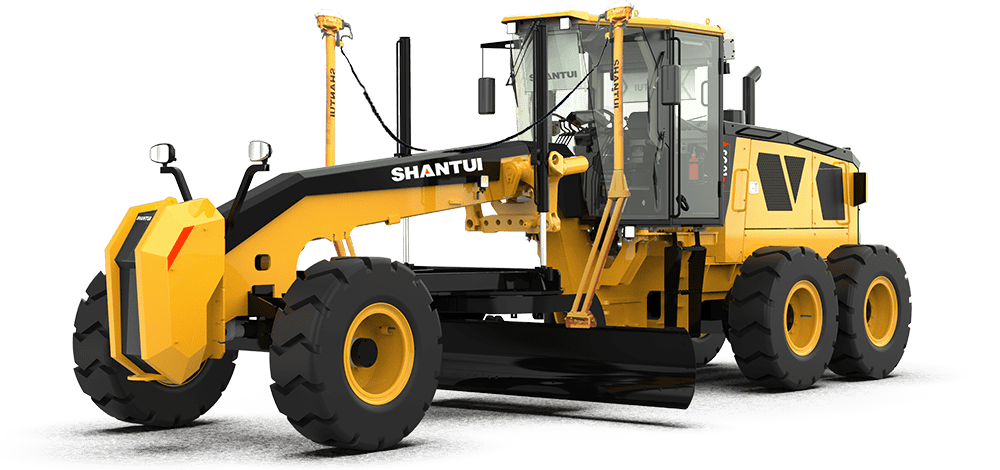

“The company aims to advance toward fully unmanned L5, building a collaborative ecosystem of ‘AI assistants + construction machine fleets,'” Shantui added. According to the plan, Shantui’s next-generation AI products will debut in 2026. Compared to L1, theoretical estimates suggest a 50% improvement in construction safety, a 40% increase in collaborative efficiency, and a 60% boost in vehicle health metrics. “The company will spend three years achieving full application of core AI functions in bulldozers, during which it will establish an AI technology platform, an intelligent construction ecosystem, and product evaluation standards. The core technology will also extend to excavators, loaders, mining trucks, graders, rollers, and other product lines, forming a ‘AI assistant + machine fleet’ collaborative ecosystem,” Shantui explained.

Su Zimeng, President of the China Construction Machinery Association, noted that the industry has entered a new phase of “digital-intelligent integration.” AI technology helps solve complex construction challenges, while smart platforms enhance supply chain efficiency, driving the leap from “single-machine intelligence” to “system intelligence.”

Construction Machinery and AI Accelerate Integration

In recent years, the construction machinery industry has continued to advance intelligent transformation, with the application of AI large models further catalyzing the intelligent upgrade of equipment. Notably, leading A-share construction machinery companies have expressed optimism about AI’s potential and are accelerating strategic deployments.

“With the continuous development and application of AI technologies like DeepSeek, the construction machinery industry will undergo unprecedented changes,” said Sany Heavy Industry. From intelligent navigation and remote control to autonomous learning and collaborative operations, AI will inject new vitality and intelligence into construction machinery products. Sany emphasized that AI and digital intelligence are key strategies, integrating digital transformation into manufacturing, products, services, and operations. The company has already launched unmanned excavators, L4 autonomous engineering vehicles, and unmanned paving and compaction fleets.

“Unmanned operations are the inevitable future of construction machinery,” stated XCMG. The company previously partnered with NetEase, leveraging its intelligent control platform to apply AI technology to machinery such as excavators and loaders. By transferring NetEase’s digital and AI capabilities from gaming to construction machinery, these products now feature remote control, cloud computing, and intelligent functions, achieving unmanned operation goals. In February 2025, XCMG’s Hancloud platform completed deep integration with DeepSeek, providing intelligent and systematic support for complex scenarios like smart IoT and intelligent manufacturing. XCMG aims to build an “AI + manufacturing” benchmark in the industry.

Meanwhile, Zoomlion has consistently invested in R&D and accelerated the application of cutting-edge technologies such as AI, cloud computing, big data, and IoT. The company ranks first in the industry for invention patent applications in big data and cloud computing. “The AI era will deepen the integration of construction machinery with the internet, big data, and cloud computing, forming a new industrial ecosystem. In the future, every product may become an ’embodied intelligent device,’ achieving single-machine intelligence + fleet collaboration,” Zoomlion stated.

Currently, AI technology has been practically applied in various construction scenarios, such as earthmoving works and complex environments, making “AI + construction machinery” a clear industry trend. “This year, AI has rapidly integrated across industries. For construction machinery, this synergy addresses long-standing pain points,” an industry insider analyzed. The deep integration of construction machinery and AI has driven comprehensive innovation in construction efficiency, safety, cost control, and maintenance models. Against this backdrop, a new wave of digital technological revolution—centered on AI, big data, and cloud computing—is accelerating industrial ecosystem restructuring, injecting fresh momentum into industry transformation.

Keywords: