In recent years, Russian builders have shifted from European machinery to Chinese-made excavators and trucks. However, high-interest loans have hindered equipment renewal, and the domestic production process has been slow. To achieve the goal of replacing 60-80% of imports by 2030, what measures need to be taken? Russian experts have shared their views.

Current State of Domestic Production: Chinese Equipment Dominates the Market

Anton Glushkov, President of the Russian National Builders Association, noted that construction machinery is the only sector in the construction industry undergoing structural changes. Although many foreign building material manufacturers exited Russia after 2022, most retained local production, and their products continue to be sold under different brands. However, the situation with road construction machinery is more complex—Russian manufacturers cannot fully meet demand, and Chinese companies have quickly filled the gap. Denis Zalnin, General Director of the development company “Lyudi,” explained that the market initially adapted to the withdrawal of foreign brands through parallel imports and the takeover of foreign assets, followed by accelerated expansion by Chinese, Turkish, Belarusian, and Indian manufacturers.

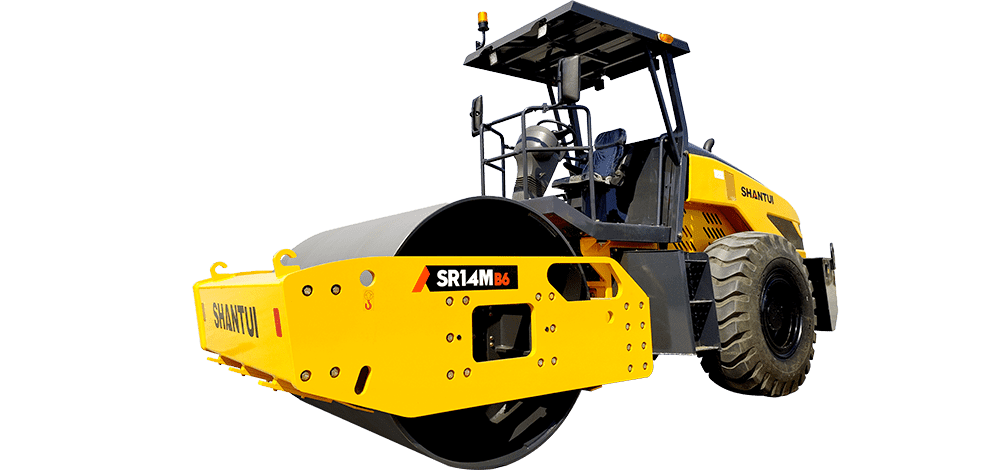

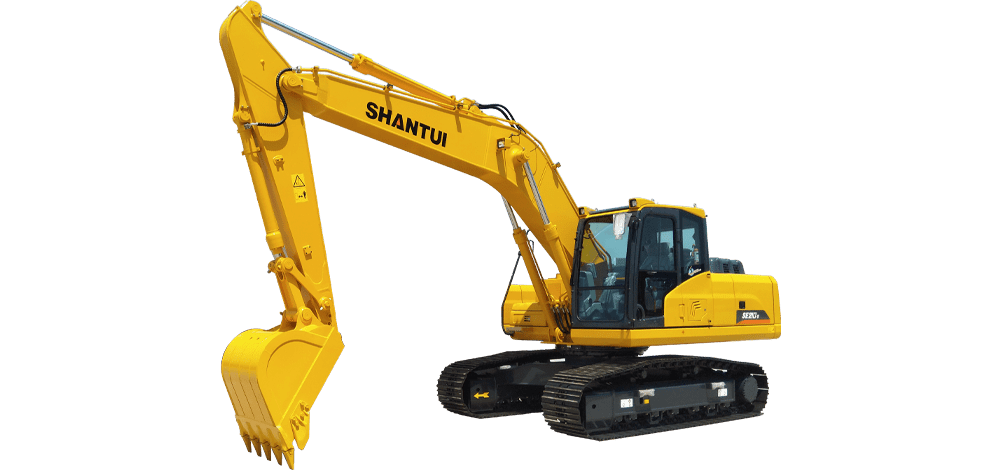

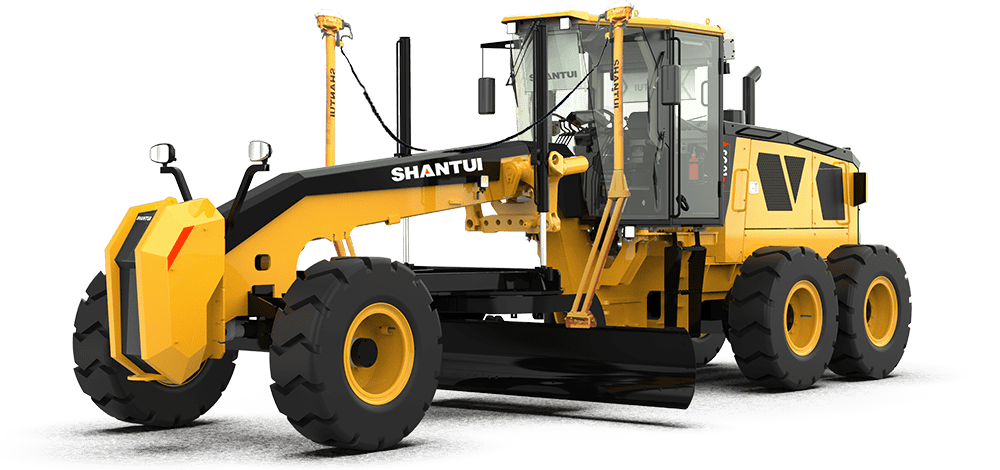

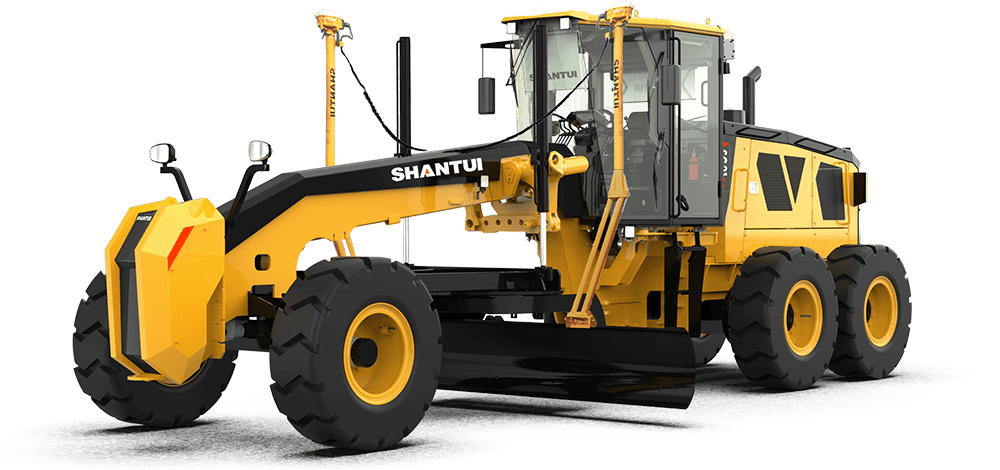

Developers have been forced to test new equipment in a short time frame, which has both advantages and disadvantages. The benefits of domestic equipment include lower logistics costs and stable parts supply. For example, Russian-made bricks have successfully replaced imports and offer greater flexibility in pricing and customization. Today, Chinese brands (such as XCMG, SHANTUI, and Sany) and Russia’s Kamaz (КАМАЗ) have replaced Western brands like JCB, Caterpillar, and Volvo.

Current Challenges: Weak Demand and High Costs Hinder Renewal

Currently, overseas manufacturers face inventory surpluses, while demand for equipment has sharply declined, primarily due to the central bank’s high interest rates, making it difficult for businesses to purchase machinery through loans or leasing. Dmitry Gavrilenko, General Director of “TSGROUP,” the parent company of specialty equipment manufacturer BEEZONE, pointed out that issues such as excessive dealer inventory, insufficient customer purchasing power, and ruble exchange rate fluctuations have exacerbated the market downturn.

He admitted, “Construction companies are short on funds, sales have plummeted, and a buyer’s market has formed.” Chinese and Indian equipment dominate the market, while a small amount of parallel-imported European and American machinery remains expensive. Gavrilenko believes that domestic production can only be partially achieved and requires government support. For example, BEEZONE’s bulldozers are marketed as “Made in Russia,” but key components still rely on imports, and local metal processing costs are too high, limiting production volumes. Forcing the use of domestic engines or transmission systems would lead to skyrocketing prices and outdated technology, so Chinese components are ultimately chosen to ensure cost-effectiveness.

Technological Bottlenecks: “Pseudo-Domestic” Production Persists

Anton Solon, Secretary of the Building Materials Division of the Russian Social Committee for Construction and Housing Utilities, stated that domestic production of road machinery has only made partial progress. Russian asphalt pavers perform adequately in regional projects, and equipment like stone spreaders and emulsion asphalt trucks have achieved local production. However, large milling machines still rely on technology from Germany’s Wirtgen or America’s Caterpillar.

Even “Russian-assembled” equipment often uses core components such as engines and hydraulic systems from China or Europe. Solon noted that the share of Chinese equipment is growing rapidly, with some even repackaged as “localized” products. Although some companies are developing fully digital domestic road machinery, over 70% of Russia’s high-end equipment still relies on imports, and domestic production even declined by 15% in 2024.

Future Path: Policy Support and Technological Cooperation Are Key

Experts believe that if sanctions persist, Chinese manufacturers’ share in government procurement (currently 60-70%) will further expand. Some equipment bypasses restrictions through “Russian assembly” certification, but this may lead to parts shortages, software dependency, and parallel import risks (e.g., hydraulic systems and electronics). Additionally, technology localization through Sino-Russian, Iranian-Russian, and Indian-Russian joint ventures could be a long-term direction.

Keywords:

Keywords: